**Title: “Taming the Titans: The Quest to 3D Print the World’s Toughest Materials”**

(What Is The Hardest Material For 3d Printing)

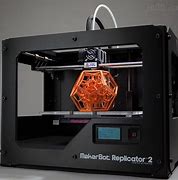

3D printing has changed how we make things. From plastic toys to metal car parts, it feels like almost anything can pop out of a printer. But there’s a catch. Not all materials play nice with 3D printers. Some are stubborn, rebellious, and downright brutal to work with. So what’s the hardest material to 3D print? Let’s dive into the gritty world of printing the unprintable.

First, think about diamonds. Yes, the shiny gems on engagement rings. Diamonds are famous for being the hardest natural material. They’re tough, heat-resistant, and perfect for cutting tools or high-tech electronics. But try printing them. It’s like asking a chef to bake a cake in a volcano. Diamonds melt at crazy-high temperatures—over 3,500°C. Most 3D printers can’t handle that heat. Even if they could, cooling diamond layers without cracks is like trying to freeze soup into a perfect ice sculpture. Scientists are experimenting with lasers and diamond dust mixtures, but so far, flawless 3D-printed diamonds are still a sci-fi dream.

Then there’s tungsten carbide. This stuff is used in drill bits, armor-piercing bullets, and anything that needs to laugh at friction. Tungsten carbide is harder than steel and almost as dense as a black hole. Printing it? Not so simple. It’s brittle, so layers often crack under stress. The material also needs to be sintered—a fancy term for baking at high temps to fuse particles. But uneven heating turns prints into crumbly messes. Companies are tweaking printer settings and mixing tungsten with binding metals like cobalt. Progress is slow, but the results are getting tougher.

Ceramics might seem harmless—after all, we make coffee mugs from them. But 3D printing advanced ceramics? That’s another story. Materials like silicon nitride or zirconia are heat-resistant and biocompatible, perfect for jet engines or medical implants. The problem? Ceramics shrink when they dry. Imagine printing a vase that turns into a shot glass. Printers have to account for shrinkage by oversizing designs. Even then, tiny flaws can cause cracks. New slurry-based printers and precise lasers are helping, but ceramic printing still feels like solving a puzzle blindfolded.

Let’s not forget graphene. This “wonder material” is a single layer of carbon atoms, stronger than steel and lighter than paper. It’s great for electronics, batteries, and even space elevators—in theory. Printing graphene is tricky. It clumps together, making smooth layers impossible. Most printers use graphene mixed with plastics or resins, which dilutes its superpowers. Researchers are testing inks and electric fields to align graphene particles. Success here could revolutionize industries, but for now, 3D-printed graphene is more hype than reality.

What about metals? Titanium and stainless steel are common in 3D printing, but their tougher cousins—like Inconel or tool steel—are nightmares. These metals resist heat and wear, ideal for rockets or molds. But they warp under high temperatures and stress. Printers need precise cooling systems and slow printing speeds to avoid defects. Even a tiny error can turn a $10,000 aerospace part into scrap.

So who’s the ultimate “titan” of 3D printing challenges? It depends. Diamonds win for pure hardness, tungsten carbide for density, ceramics for fussiness, and graphene for potential. Each material fights the printing process in its own way. The common thread? All require insane precision, creative workarounds, and a lot of failed prototypes.

(What Is The Hardest Material For 3d Printing)

The race to conquer these materials isn’t just about bragging rights. It’s about building better medical devices, greener energy systems, and faster machines. Every cracked layer or warped print teaches engineers something new. Maybe one day, 3D printers will tame these titans as easily as printing a plastic keychain. Until then, the battle between human ingenuity and stubborn materials rages on.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)