**How To Spot 3D-Printed Stuff: A Detective’s Guide To Material Mysteries**

(How To Identify 3d Printed Material)

You find a cool plastic gadget on your desk. Is it factory-made or fresh off a 3D printer? Telltale signs hide in plain sight. Let’s break down how to play material detective.

**Look For Layer Lines**

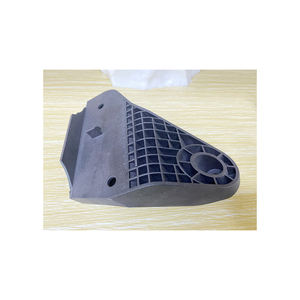

3D printers build objects layer by layer. Imagine stacking pancake batter one thin round at a time. The result? Tiny ridges on the surface. Tilt the object under light. Spot faint parallel lines? That’s a smoking gun. Smooth surfaces like glass or polished plastic won’t have these. Injection-molded items are slick. 3D-printed ones? They’re like topographic maps.

**Check For Tiny Zits Or Strings**

Sometimes printers ooze extra plastic. These blobs harden into zits. Thin wisps of plastic might dangle like cobwebs. Factory-made items don’t have these flaws. If you see random bumps or hairs, think 3D printer.

**Feel The Texture**

Run your finger over the surface. 3D-printed plastic feels rough. It’s like fine sandpaper. Some makers sand it down, but edges or corners stay gritty. Factory plastic? Smooth as butter. Resin prints feel different. They’re smoother but often sticky or waxy.

**Test The Weight**

3D prints are usually lightweight. Printers use infill patterns—grids or honeycombs inside—to save material. Pick up the object. Does it feel lighter than it looks? Compare it to a similar store-bought item. A 3D-printed spoon might weigh less than a Walmart version.

**Do The Tap Test**

Flick the object with your fingernail. Listen. A hollow, dull “thunk” suggests infill patterns inside. A solid “clunk” hints at traditional manufacturing. This isn’t foolproof, though. Some prints use 100% infill.

**Sniff It Out**

Fresh 3D prints smell. PLA plastic gives off a sweet, almost sugary scent when printed. ABS? It smells like burnt plastic. If the object has a faint “burnt toast” vibe, it might be 3D-printed. Factory items don’t have odors unless painted or treated.

**Look For Support Scars**

Printers need support structures for overhangs. These get snapped off later. Check under arches or around complex shapes. See rough patches or broken nubs? That’s where supports were attached. Smooth surfaces there? Probably not 3D-printed.

**Spot The Color Limits**

Most home printers use one color at a time. Multi-color prints exist but are pricey. If an object has rainbow shades or gradients, it’s likely factory-made. Single-color items with painted details? Maybe 3D-printed. Check for brush strokes or uneven spray paint.

**Examine The Bottom**

The first layer of a print often leaves a pattern. Look at the base. See a grid, dimples, or lines? That’s the printer’s build plate texture. Factory items have uniform bottoms.

**Watch For Warping**

Plastic shrinks as it cools. Corners might curl up like old book pages. Check edges. Lifted or wavy sections? Warping points to 3D printing.

**Look For Brand Marks**

Some printers leave logos. MakerBot items sometimes have a tiny “MB” stamp. Check hidden spots. No brand mark doesn’t mean it’s not printed—but a logo screams “I was 3D-printed!”

**Check The Price Tag**

Custom shapes or intricate designs cost a fortune if factory-made. 3D printing cuts costs for small batches. If it’s cheap but looks complex, suspect printing.

(How To Identify 3d Printed Material)

Armed with these tricks, you’re ready to crack the case. Next time you spot a suspicious plastic doodad, play detective. Peek, poke, and prod. The clues are there—you just gotta know where to look.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)